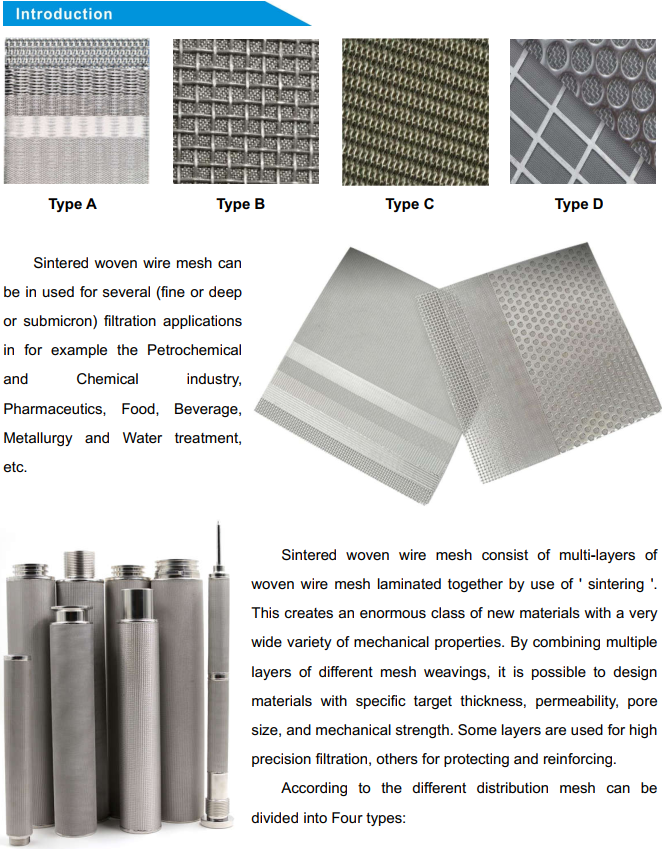

Standard 5-layer sintered woven wire mesh (Type A)

Standard sintered five-layer mesh consists of the protective layer, the filter layer, the dispersion layer, and two reinforcing layers. It is the most commonly used type.

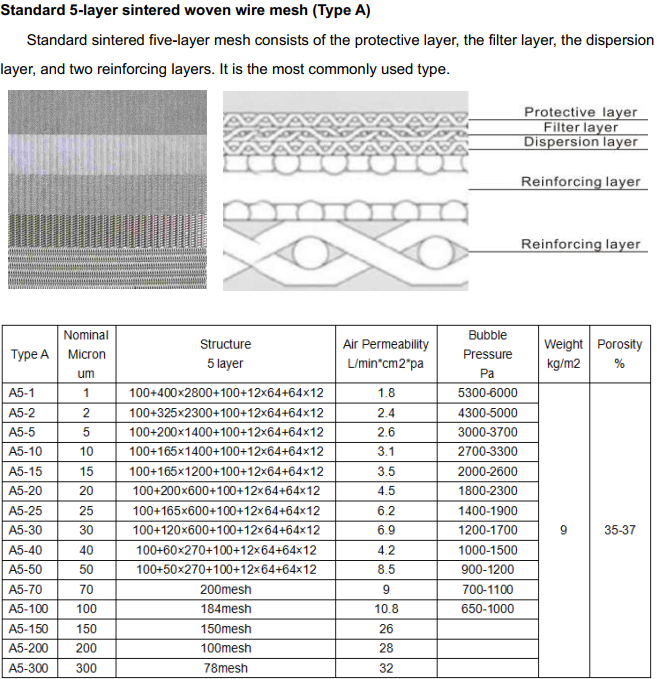

Sintered square woven wire mesh (Type B)

This type of Sintered wire mesh is made by sintering multiple layers of plain weaven square woven wire mesh together. Because of the layer open are pecentages of the square woven wire mesh layers,this type has good permeability and low combination to achieve particular flow and filtration characteristics.

This type sintered wire mesh is usedful for polymer prodcution as well as variety of fluid and air filtration applications.

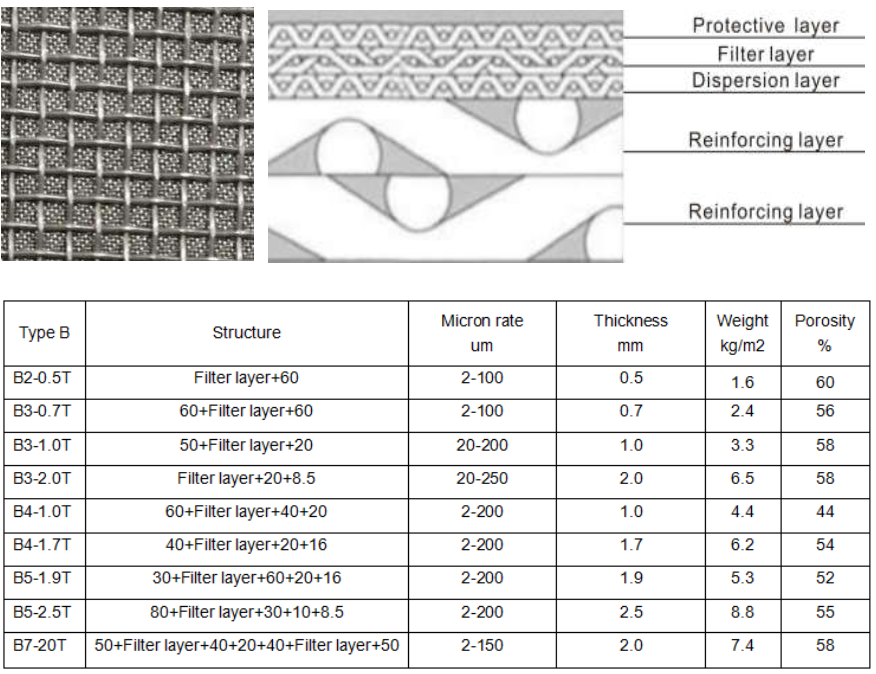

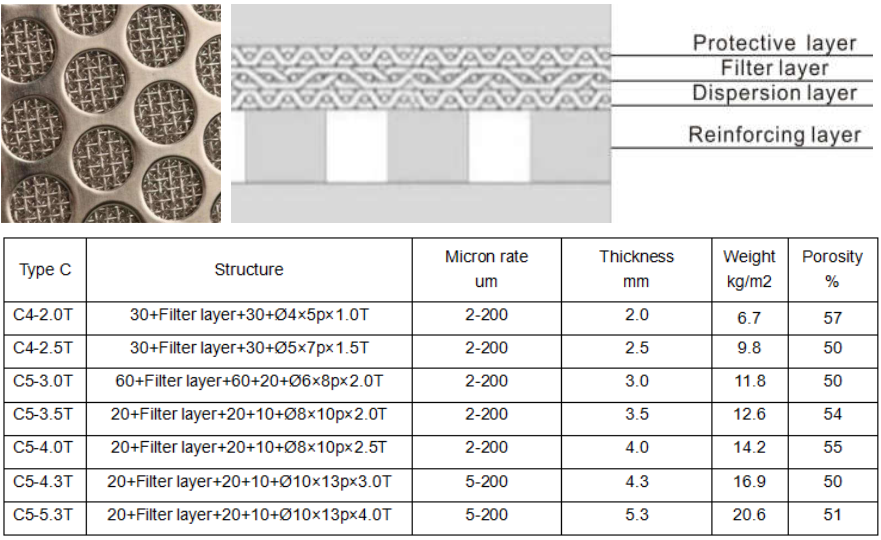

Dutch woven sintered wire mesh (Type C)

This kind of sintered wire mesh laminate is made by sintering 2-3 layers of plain Dutch woven wire mesh together.This kind of stainless steel sintered wire mesh laminate has evenly spaced openings and good air permeability to flow.It also has ever good mechanical strength due to the heavy Dutch woven wire mesh layers.

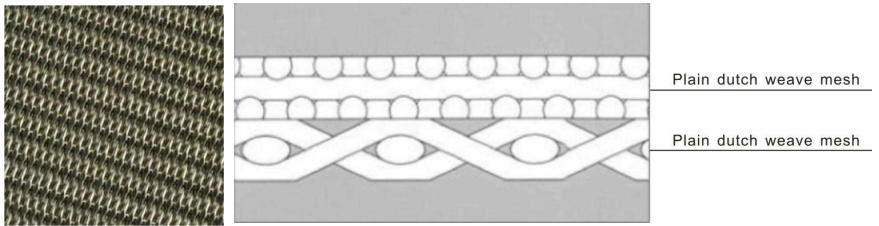

Perforated sheet sintered with wire mesh laminate (Type D)

This type is made by taking several layers of woven wire mesh sintered them on a layer of perforated meta forming a very strong yet tractable filter mesh sheet.

Feature:

1. High strength and rigidity: extreme mechanical strength and pressure tolerance, can be

machined, welded and assembled

2. Uniform and stable precision: consistent filter property in various media, without apertures

changing during operation

3. Widely service environment: can be continuously in temperature ranging from-200℃ to 600℃

and filtering in acid and alkali conditions.

4. Cleanable: backwash easily, and reused with longer service span, and can be cleaned by means

of ways, such as backstream, filtration liquid, ultrasonic, dissolution and baking

5. High flow, low pressure drop

6. Suitable for continuous and automatic operation

Common filter element: