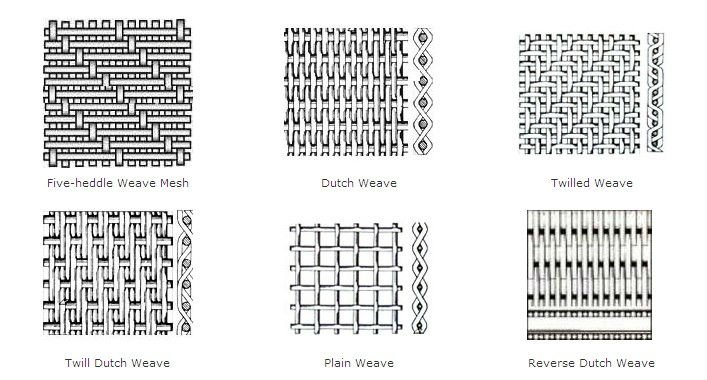

Plain weave

Also called tabby weave, linen weave or taffeta weave, is the most basic type of weaves. In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under the warp threads that its neighbor went over, and vice versa.

Twill net

Twilled weave” is a weave type in which the warp wires and shute wires pass over two and under

two in both directions. This is different from a plain weave, which is when the wires are woven one

over and one under. As a result, “twilled weave” is often more pliable than a comparable plain

weave wire mesh specification. By and large, twilled weave is often used in filtration applications.

The images below illustrate twilled weave, but because twilled weave is usually reserved for fine me

sh, identifying a twilled weave usually requires a mesh counter.

Mesh/inch | Wire Diameter(mm) | Aperture (mm) | Mesh/inch | Wire diameter(mm) | Aperture (mm) |

2mesh | 1.80 | 10.90 | 60mesh | 0.15 | 0.273 |

3mesh | 1.60 | 6.866 | 70mesh | 0.14 | 0.223 |

4mesh | 1.20 | 5.15 | 80mesh | 0.12 | 0.198 |

5mesh | 0.91 | 4.17 | 90mesh | 0.11 | 0.172 |

6mesh | 0.80 | 3.433 | 100mesh | 0.10 | 0.154 |

8mesh | 0.60 | 2.575 | 120mesh | 0.08 | 0.132 |

10mesh | 0.55 | 1.990 | 140mesh | 0.07 | 0.111 |

12mesh | 0.50 | 1.616 | 150mesh | 0.065 | 0.104 |

14mesh | 0.45 | 1.362 | 160mesh | 0.065 | 0.094 |

16mesh | 0.40 | 1.188 | 180mesh | 0.053 | 0.088 |

18mesh | 0.35 | 1.060 | 200mesh | 0.053 | 0.074 |

20mesh | 0.30 | 0.970 | 250mesh | 0.04 | 0.061 |

26mesh | 0.28 | 0.696 | 300mesh | 0.035 | 0.049 |

30mesh | 0.25 | 0.596 | 325mesh | 0.03 | 0.048 |

40mesh | 0.21 | 0.425 | 350mesh | 0.03 | 0.042 |

50mesh | 0.19 | 0.318 | 400mesh | 0.025 | 0.0385 |

Next : Iron chromium aluminum fiber felt

Previous : Multilayer metal sintered wire mesh